One thing I have always understood is that life is about choices. Humans have to make an innumerable amount of choices on a daily basis. Every once in a while we are confronted with important decisions. Lately it feels like my batting average on these important decisions is below the Mendoza Line.

Anyway, this all started at the end of September at a North Shore Brewers club meeting. Club Vice President Tim Broderick listed off the club members that had volunteered to brew for the upcoming Ales over ALS competition and event. As Tim read off the names, participation felt light. I haven't brewed for the event since before the pandemic. In 2021 and 2022, I served as a judge and was penciled in to judge again in 2023. After a few beers, I told Tim "If you need me to pour beer instead of judge, let me know". Then I completely forgot about volunteering until Tim messaged me a few days later.

|

| Broken First IPA and Potrero Hill Porter |

Now, my history at this event has been fraught. I've had near-misses where I've brought solid beers and almost won the People's Choice and the Judge's Choice. I've also brought a beer and a cider that were completely trashed by the judges. Deserved or not, it stung and I left the event enraged and embarrassed. If I was going to pour and compete again at this event, I was going to put my best foot forward.

At the time I volunteered, I had two beers on tap: an extract version of my Derby Wharf Porter and Inverted Fest. Neither beer was terrible, but neither were great. The porter was under-hopped because I used homegrown hops and guestimated the bitterness. The marzen was an experimental recipe that missed the mark.

That meant I had to brew at least one new batch, and I had to brew right away!

In the past I had always brought two beers to the event, so I decided to make time for a double brew day. That would also give me a hedge in case there was an issue with one of the two beers. If both beers were clean, then I would have to choose which one to enter for judging.

When it came to choosing what to brew, and the brew day itself, I was going to leave nothing to chance. I was going to brew two proven recipes. I was going to cut no corners in sanitizing equipment, brewing, cellaring, packaging, and serving these beers.

The first thing I did was to scan my brew log for ideas. I wanted to find a past recipe that came out the way I wanted and that I was confident I could replicate. There were a few that stood out, but ultimately I narrowed it down to Broken Fist IPA.

For my other brew, I looked through my folder of recipe ideas I wanted to brew but had not yet. One recipe was an Anchor Porter clone. Sadly, Anchor Brewing closed over the summer so it felt like a perfect time to brew this beer. The recipe was based on a clone published in Brew Your Own, so I was confident the recipe was sound.

|

| I forgot how expensive hops can be when brewing IPAs. |

With recipes selected, I wanted to be sure to use the freshest ingredients possible. That meant fresh pitches of yeast to ensure there were no issues with fermentation. It also meant fresh hops right out of the bag, as opposed to hops that have been sitting in my fridge for who knows how long. Fresh hops being especially important in an IPA.

On brew day I started brewing the porter first. I chewed on the Mapleton Pale malt I was using as the base. It tasted a little stale, but it was what I had and it was too late to buy fresh malt at that point. I milled my grains and mashed in.

|

| Bleach is the best sanitizer for glass or plastic. |

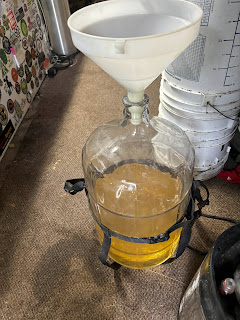

During the mash, I made a bleach solution to sanitize the glass carboy I was fermenting in. No chance I was going to risk this batch fermenting in plastic! Bleach is a primitive sanitizer compared to modern no-rinse sanitizers available to homebrewers now. It needs more contact time and needs to be rinsed, but in my opinion it is still the most effective. Bleach will cause pitting on stainless steel, but for glass and plastic it's bulletproof. I encourage everyone to sanitize their gear with a bleach solution at least once a year, if not every batch.

After my mash, I took a refractometer reading and saw my mash efficiency was way down. It was 65% to be exact, much lower than the 80% I typically achieve when fly sparging. To make up for the miss, I added all of the dry malt extract I had to hit my target pre-boil gravity.

|

| Leaving nothing to chance by sanitizing twice. |

During the boil, I rinsed my carboy with water, made an Iodine sanitizer solution, and re-sanitized everything that would touch my beer. Overkill? Perhaps.

After the boil and cooling down my wort, I aerated my wort for a good twenty minutes. An Anchor clone has to use Anchor's ale yeast. The pitch I bought at the homebrew shop was only a few weeks old, but I wanted to give the yeast all the help I could. I also added yeast nutrient at the end of the boil.

|

| A well-aerated wort helps the yeast produce new cells. |

For my second brew, I tried a couple things to help address the poor yield in my first brew. I milled the grain twice, and fly-sparged extra slow. Those steps helped a little as my mash efficiency was almost 70%, but I was still off my target pre-boil gravity. Having used up all of my dry malt extract in the first brew, the only source of sugars I had to supplement was a few ounces of corn sugar. I threw it in and hoped for the best.

|

| An absolute BEAST, best Chico variant I have ever used. |

I've used a couple of different yeast strains in the past with Broken Fist. This time I used Fermoale AY4 from AEB, which is their American Ale/Chico strain. This is one of the dry yeasts I sell at Pro Brew Supply and I was excited to try it, and to try an AEB yeast for the first time.

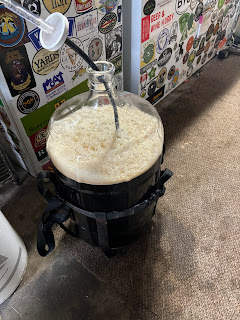

After filling both carboys, I placed them in separate fermentation chambers and cooled them to my pitching temp before pitching my yeast. Typically, in my experience dry yeast starts a little more slowly compared to liquid yeast. That did not happen here at all. The AY4 took off within 12 hours, while the liquid took 24-36 to really get going. Broken Fist got it's first small dry hop on Day 4, and both beers were racked to 5-gallon carboys for secondary fermentations on Day 8.

At this point I had to tell Tim what beer I wanted to have judged. The IPA tasted green, but promising. The porter was a little harsh, but would probably mellow after a couple more weeks in secondary. I decided the porter was the safer play. I was concerned that by missing my target gravity, the IPA would be too bitter. IPAs are also more vulnerable to oxidation.

Most IPA brewers go to great lengths to shield their beer from oxygen such as pressurized transfers with CO2, dry hopping under pressure to trap hop oils and aromas, or use fittings on a stainless steel fermenter to add their dry hops with no oxygen exposure. My cheaper, old-school setup doesn't have any of those bells and whistles. It had also been a long time since I brewed an IPA that I was really happy with. In my mind it just felt like more could go wrong with the IPA.

Three days before packaging, I cold crashed the porter and fined it with gelatin. I lowered the temperature on the IPA to 54F and once it hit that temperature, added the main dry hop charge. On packaging day, I purged the crap out of both kegs before siphoning the beer into kegs. The IPA was fined with gelatin on kegging day.

|

| All set up and ready to pour! |

Much to my relief, both beers were very good.

The judges gave Potrero Hill Porter scores of 33, 34 and 37. Those scores placed the beer in the "Very Good" range, but shore of "Excellent" (38-44 points). Two takeaways from their feedback were the body was a little to light, and the roasted character maybe a touch harsh.

Looking at my brew sheet the target FG was 1.015, but the beer actually finished at 1.011. That four points of gravity may have made a difference. There are a couple ways I could correct that. I could mash higher next time, or at least check and adjust my mash temperature to make sure it does not drop. I could also use more Crystal Malt. That would give the beer more unfermentable sugars and body, and additionally more caramel sweetness to balance the roasted malts.

Tasting both beers the day of the event, I was shocked at how much I enjoyed the hop aroma with Broken Fist. If there was one thing I haven't loved about my IPAs over the years is that they didn't blow me away with hop aroma like say a Trillium IPA would.

The hop bitterness was firm, the beer finished crisp but not harsh. The flavor was hop forward with lots of citrus, but with a semblance of bready malt flavor with a hint of vanilla.

What might have impressed me the most was how gorgeous this batch of Broken Fist came out. It was clearer than some of the lagers I have brewed in the past. It also had a moderate white head with excellent retention that helped trap those hop aromas.

I counted at least five attendees who said they would have voted for the IPA for People's Choice if that was the beer I had entered. The brewer pouring next to me kept asking for more pours of the IPA. After the judging was completed, all three judges said I should have entered Broken Fist. One judge who loves West Coast IPA, said he enjoyed my beer more than any of the commercial beers at the event. Score that another decision I swung and missed on!

Tasting all of the homebrew entries, there was not a clunker in the bunch. My scores were good for third place in the judging. People's Choice went to the one mead-maker in the club. Mead and cider played well with the locals from Essex, Massachusetts. Also with half a dozen local breweries, a kombucha maker, and wine, many of the attendees didn't make it to where the homebrewers were set up.

Winning this thing is kind of my white whale as a homebrewer. I've had both close calls and abject failures. I feel like I need to win at least once to redeem both. In the meantime, I may need to bottle off some Broken Fist and see how it does in another competition.

Follow me on Instagram @wouldbebrewmaster

Like The Would-be Brewmaster on Facebook

Share what beers you are drinking with me on Untappd

Recipe: Potrero Hill Porter Brewer: Jason Chalifour Style: American Porter TYPE: All Grain Taste: (34.7) Recipe Specifications -------------------------- Boil Size: 6.35 gal Post Boil Volume: 5.68 gal Batch Size (fermenter): 5.25 gal Bottling Volume: 5.00 gal Estimated OG: 1.061 SG Estimated Color: 40.0 SRM Estimated IBU: 44.1 IBUs Brewhouse Efficiency: 65.60 % Est Mash Efficiency: 68.1 % Boil Time: 60 Minutes Ingredients: ------------ Amt Name Type # %/IBU Volume 7.71 gal Black Full (Over 31 SRM) Water 1 - - 3.37 g Chalk (Mash) Water Agent 2 - - 2.35 g Baking Soda (Mash) Water Agent 3 - - 2.31 g Epsom Salt (MgSO4) (Mash) Water Agent 4 - - 8 lbs 8.0 oz Mapleton Pale Malt (Maine Malt) (2.0 SRM) Grain 5 70.5 % 0.66 gal 1 lbs Crystal 110 (40L) (Muntons) (55.8 SRM) Grain 6 8.3 % 0.08 gal 8.0 oz Black Malt (Muntons) (634.5 SRM) Grain 7 4.1 % 0.04 gal 8.0 oz Chocolate Malt (Muntons) (520.3 SRM) Grain 8 4.1 % 0.04 gal 1 lbs 9.0 oz Spraymalt DME - Light [Boil] (5.0 SRM) Dry Extract 9 13.0 % 0.12 gal 1.25 oz Northern Brewer [7.30 %] - Boil 60.0 min Hop 10 31.8 IBUs - 0.75 oz Northern Brewer [7.30 %] - Boil 15.0 min Hop 11 12.3 IBUs - 1.05 tsp Yeast Nutrient (Primary) Other 12 - - 1.0 pkg American Ale II (Wyeast Labs #1272) [124.21 ml] Yeast 13 - - 0.50 tsp Gelatin (Secondary 4.0 days) Fining 14 - - Mash Schedule: Single Infusion, Medium Body, No Mash Out Total Grain Weight: 12 lbs 1.0 oz ---------------------------- Name Description Step Temperat Step Time Mash In Add 3.38 gal of water at 165.6 F 154.0 F 60 min Sparge: Fly sparge with 4.33 gal water at 168.0 F Notes: ------ Yield poor. Base malt tasted a little stale, could have picked up moisture. Only 1/2" water above grain bed. Sparge temp may have also dropped. Added DME to compensate.20 mins aeration with aquarium pump. Added yeast nutrient to compensate for not making a yeast starter. Pitched at 68F, set temp for 66F. Day 8, racked 7bx. beer very green and harsh 10/25 pulled samples, smoothed out. still finishes a little astringent when warm 10/26 started cold crash and fined with gelatin.Recipe: Broken Fist IPA Brewer: Jason Chalifour Style: American IPA TYPE: All Grain Taste: Recipe Specifications -------------------------- Boil Size: 6.61 gal Post Boil Volume: 5.94 gal Batch Size (fermenter): 5.50 gal Bottling Volume: 5.00 gal Estimated OG: 1.053 SG Estimated Color: 3.7 SRM Estimated IBU: 52.6 IBUs Brewhouse Efficiency: 69.40 % Est Mash Efficiency: 71.9 % Boil Time: 60 Minutes Ingredients: ------------ Amt Name Type # %/IBU Volume 4.00 gal Distilled Water Water 1 - - 4.00 gal Salem/Beverly, MA Water 2 - - 1.90 g Gypsum (Calcium Sulfate) (Mash) Water Agent 3 - - 1.00 tsp Lactic Acid (Mash) Water Agent 4 - - 0.50 g Epsom Salt (MgSO4) (Mash) Water Agent 5 - - 10 lbs 8.0 oz Mapleton Pale Malt (Maine Malt) (2.0 SRM) Grain 6 93.1 % 0.82 gal 8.0 oz Carapils (Briess) (1.5 SRM) Grain 7 4.4 % 0.04 gal 2.32 g Gypsum (Calcium Sulfate) (Sparge) Water Agent 8 - - 0.50 tsp Lactic Acid (Sparge) Water Agent 9 - - 0.45 g Epsom Salt (MgSO4) (Sparge) Water Agent 10 - - 0.50 oz Chinook [11.10 %] - First Wort 60.0 min Hop 11 21.5 IBUs - 4.4 oz Corn Sugar (Dextrose) [Boil] (0.0 SRM) Sugar 12 2.4 % 0.02 gal 0.50 oz Cascade [6.80 %] - Boil 15.0 min Hop 13 7.7 IBUs - 0.54 tsp Irish Moss (Boil 10.0 mins) Fining 14 - - 1.50 oz Citra [12.00 %] - Steep/Whirlpool 15.0 min, 194 Hop 15 15.4 IBUs - 0.50 oz Cascade [5.50 %] - Steep/Whirlpool 15.0 min, 19 Hop 16 2.4 IBUs - 0.50 oz Chinook [13.00 %] - Steep/Whirlpool 15.0 min, 1 Hop 17 5.6 IBUs - 1.0 pkg Fermoale AY4 (AEB #AY4) [50.28 ml] Yeast 18 - - 0.50 oz Citra [12.00 %] - 3.0 Days Into Primary for 4.0 Hop 19 0.0 IBUs - 2.00 oz Citra [12.00 %] - 3.0 Days Before Bottling for 3 Hop 20 0.0 IBUs - 1.00 oz Cascade [6.80 %] - 3.0 Days Before Bottling for Hop 21 0.0 IBUs - 1.00 oz Chinook [11.10 %] - 3.0 Days Before Bottling for Hop 22 0.0 IBUs - 0.50 tsp Gelatin (Bottling) Fining 23 - - Mash Schedule: Single Infusion, Light Body, No Mash Out Total Grain Weight: 11 lbs 4.4 oz ---------------------------- Name Description Step Temperat Step Time Mash In Add 3.54 gal of water at 158.8 F 148.0 F 75 min Sparge: Fly sparge with 4.49 gal water at 168.0 F Notes: ------ After poor yield with Potrero Hill Porter, I milled grain twice and sparged extra slow. Yield improved but still down from my usual 75-80%. Used all of my Light or Extra Light DME in porter. All I had to bump gravity was a little bit of corn sugar. Racked on Day 8. Hazy and tasted grassy and harsh 5.75 bx. 10/25 lowered temp to 54F 10/26 dry hop

No comments:

Post a Comment